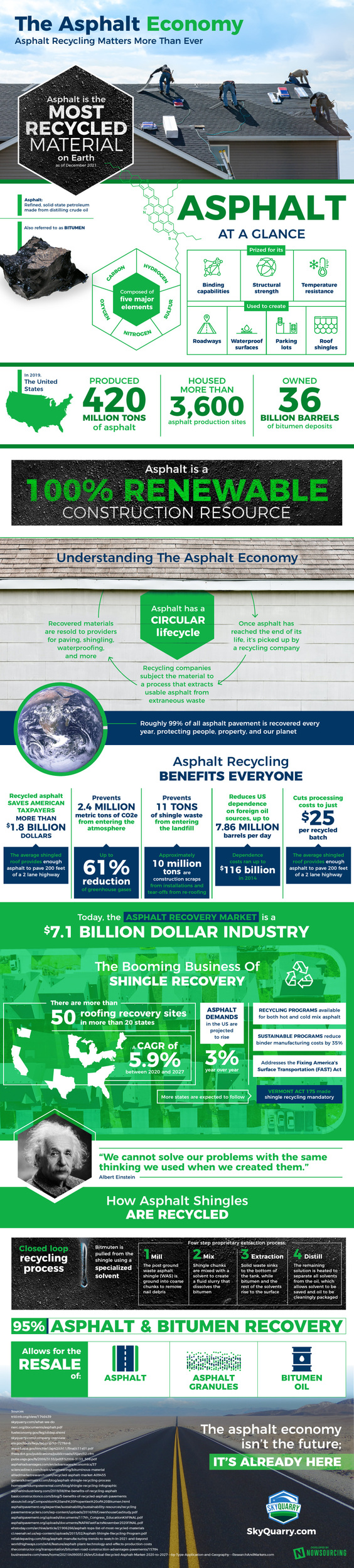

As the currently most renewable construction material on Earth, asphalt is valued for its binding and temperature resistance qualities as well as for its dependable strength. It is considered refined petroleum in its solid form and is produced from crude oil. Also defined as bitumen, asphalt is made up of elements such as hydrogen, carbon, and nitrogen.

A large amount of asphalt is produced, housed, and used in the U.S. In 2019 alone the country accumulated 420 million tons of asphalt while having at least 3,600 asphalt production sites in use. Almost 40 billion barrels of bitumen particles were also stored in the U.S. in the same year.

One of the reasons asphalt is such a renewable resource is due to its circular life cycle. Old asphalt can be given new life by being reclaimed by a recycling company that exposes the material to an extraction process that separates the usable asphalt from the portions that cannot be used again. The collected materials are converted to new asphalt and resold so they can once again be used for shingling, paving, and waterproofing projects. In fact, roughly 99% of asphalt (especially asphalt used for pavement) is recovered each year and recycled, helping to save our planet.

Asphalt recycling is beneficial for a variety of reasons. For one, recycling asphalt stops tons of CO2e, or carbon dioxide equivalent, from entering the atmosphere and creating greenhouse gases. Another reason is that recycling decreases the number of foreign oil sources the U.S. uses by almost 8 million barrels per day, which saves the country money considering that dependence costs ran up to $116 billion according to 2014 data. Processing costs can decrease to just $25 per batch and save American taxpayers at least $1.8 billion as well by recycling asphalt.

The shingle recovery business has been gaining momentum as the asphalt recovery market continues to rise. More than 20 U.S. states have at least 50 roofing recovery areas with recycling programs available for cold and hot mix asphalt. If you’re wondering about “recycling near me“, consider that these programs are widespread and accessible in many regions. Demands for asphalt are expected to rise 3% each year as sustainable programs continue to decrease binder manufacturing costs by 35%. Shingle recycling has actually become mandatory in the state of Vermont with Act 175, and other states are expected to enact similar shingle recycling laws in the near future.

Asphalt shingle recycling is typically a closed-loop process that extracts bitumen using a specialized solvent. First the waste asphalt shingle (WAS) is crushed into looser pieces to get rid of unwanted debris. A solvent is then added to the shingle pieces to create a liquid sludge that breaks down the bitumen which rises to the surface as the solid bits of waste land at the bottom of the container. Finally, the leftover solution is exposed to heat so the rest of the solvents are separated from the oil, allowing the solvent to be reused and the oil to be packaged.

95% of recovered bitumen and asphalt can be resold as asphalt, asphalt shingles, and bitumen oil, making the recycled asphalt market a very sustainable industry.

Source: InvestSkyQuarry.com